News & Events

Ceit promotes digitalisation and sustainability of additive manufacturing with MADISON

13 | 02 | 2025

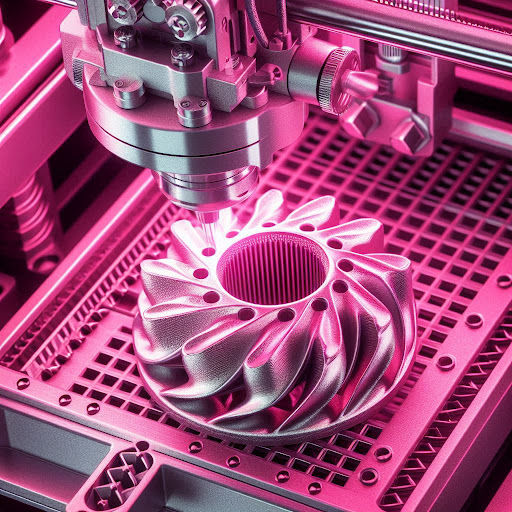

MADISON seeks to improve additive manufacturing (AM) processes of metal materials via advanced simulations and the development of new alloys for their industrial application.

Ceit plays a key role in optimising AM processes by focusing on the simulation of materials, thermal treatment and advanced monitoring to ensure quality and sustainability.

Additive manufacturing (AM) is revolutionising industrial and scientific sectors, as it enables customised parts to be obtained with a high level of precision, which reduces material wastage and improves energy efficiency. This in turn facilitates the digitalisation of workflows, thus enabling them to adapt to changes in demand with lower costs and production times.

Within this context, the MADISON project seeks to help develop new features throughout the AM value chain via a holistic notion of all its associated processes: ranging from the manufacturing and characterisation of metal powders (raw material), the development of the process for new materials and an improvement in the process involving already-processable materials (intermediate product), to the generation and validation of test methodologies for parts produced using these techniques in order to establish them as a production process on an industrial scale (finished product).

MADISON, promoted by the Ceit, Aidimme, Catec, eta Lortek technology centres, is one of the twelve projects funded by the CDTI (Centre for the Development of Industrial Technology) via grants destined for Cervera Technology Centres of Excellence 2023.

Excellence in Additive Manufacturing

The main goal of MADISON is to tackle current limitations in terms of AM when applied to metal materials. The consortium works on improving titanium alloys (Ti64), copper, aluminium alloys, steels and nickel superalloys. To this end, advanced simulations and metal powder manufacturing are used by applying high-precision and post-processing additive technologies in order to improve these materials under extreme conditions.

The role of Ceit in optimising additive manufacturing

The Ceit Technology Centre is playing a key role in the MADISON project thanks to its experience in process simulation and material optimisation. In particular, Ceit is in charge of microstructural modelling of materials such as copper and nickel superalloys. Using thermodynamic simulations and experimental tests, the centre optimises the manufacturing parameters with a view to enhancing the performance of these materials under extreme conditions.

Ceit is also contributing via its experience in atomisation process modelling in order to understand the operational variables that have the most influence on the characteristics of atomised powder and to modify atomisation units in such a way as to improve their performance in additive manufacturing applications.

Another aspect in which Ceit is providing a significant contribution is in the thermal treatment of manufactured parts, which enables their mechanical and microstructural properties to be enhanced. Additionally, Ceit is implementing advanced monitoring technologies to detect faults during manufacture and to ensure the quality of the parts produced.

Prominent advances

Among the most important advances achieved by Ceit is the successful atomisation of GRCop-42 powder – a copper alloy with high thermal conductivity, originally developed by NASA. This material has been processed using the PBF-L (Laser Powder Bed Fusion) technique, with promising results being obtained. The centre hopes to be able to study its processability using different AM technologies.

Additionally, Ceit is installing the second L-DED (Laser Directed Energy Deposition) cell at its premises, which will enable work to be undertaken on fine wire-based depositions using materials such as aluminium, titanium and bronze. Likewise, it is developing new powder metallurgy grades of more sustainable stainless steels using BJT/M (Binder Jetting). Among these is Nitronic – a family of austenitic stainless steels that provide an excellent combination of corrosion resistance and mechanical properties at cryogenic temperatures, and which have great potential in applications related to the hydrogen economy.

Dissemination of results and participation in international events

The dissemination of advances is a key activity in the MADISON project, In this sense, Ceit has actively taken part in international fairs such as BIEMH, Formnext, with its own stand, and at congresses such as EuroPM 2024 (Malmo, Sweden), WorldPM 2024 (Yokohama, Japan) and ICAM (Atlanta, USA).

Commitment to sustainability

The MADISON project not only focuses on technological enhancement, but also on sustainability in terms of additive manufacturing processes. Ceit is conducting an exhaustive analysis of the sustainability of new processes, seeking to minimise environmental impact and ensuring that advances be viable in the long term.

The project points to very different sectors, among which are aeronautics, space, energy, scientific installations, health, capital goods, machine tools and the car-transport industry. All of these are sectors with high added value and are keys to the economic development of the territory, with a high technology component.

![]()