News & Events

Ceit promotes innovation in sustainable magnets to foster European energy autonomy

18 | 11 | 2024

The project seeks to pave the way towards a more autonomous and greener Europe within the energy and sustainable mobility context.

The Ceit Technology Centre will be playing a fundamental role by producing large batches of metal powders deriving from brand new alloys needed to manufacture new magnets, and by researching into critical aspects of the atomisation process using numerical simulation and experimentation.

The transition towards cleaner energy amd environmentally friendly mobility is essential to ensure that Europe attains its carbon neutral objectives, as set out in the European Green Deal. However, these advances depend on critical raw materials, especially rare earths, which are essential for the manufacture of permanent magnets. Currently, over 90% of these materials come from China, which highlights the vulnerability in terms of the development of European strategic sectors such as renewable energies and the electric vehicle sector.

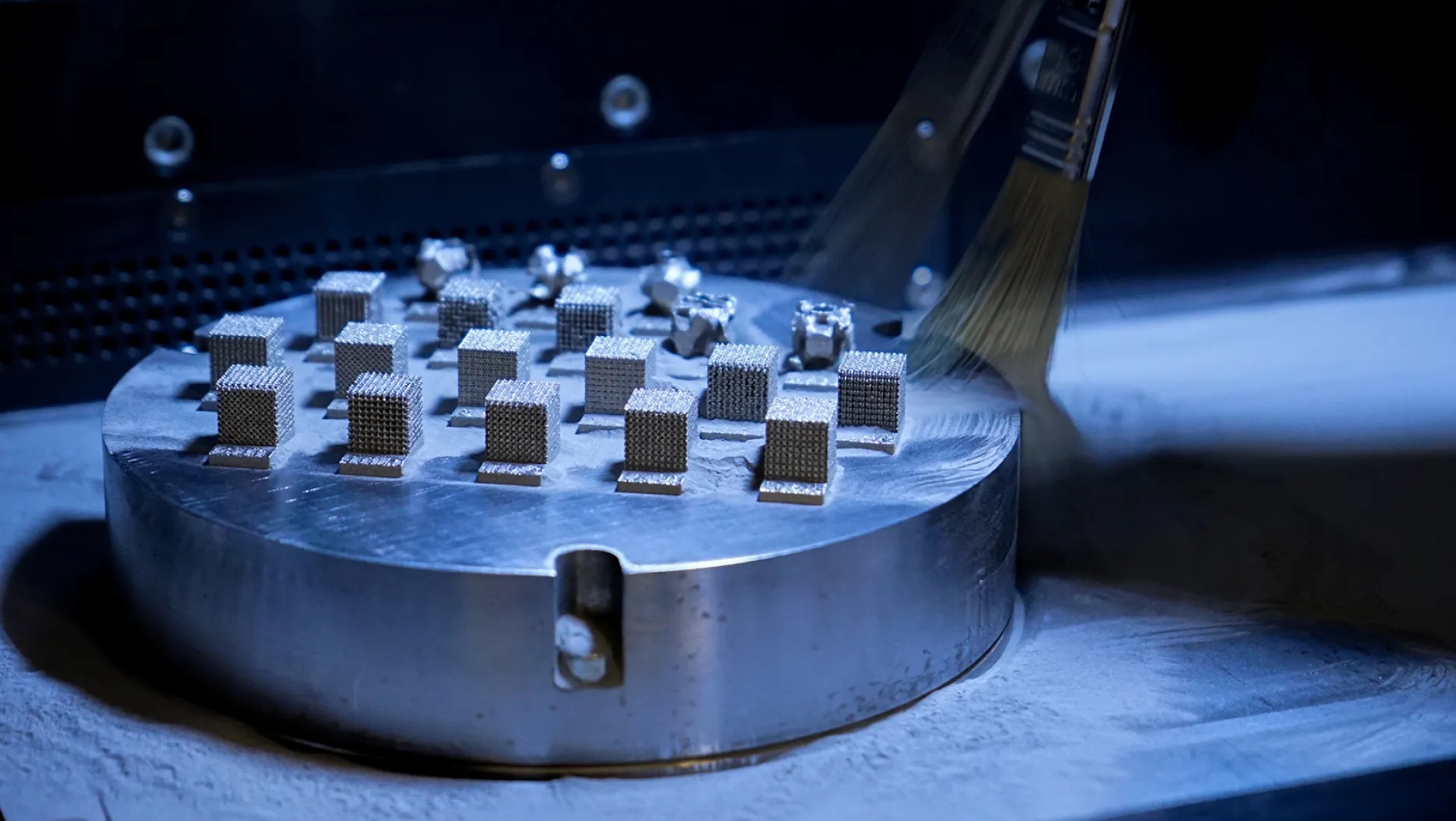

To face up to this challenge, Ceit is taking part in MagNEO, a European project funded by 7.7 million Euros to develop a new generation of sustainable magnets that are free of rare earths. This initiative seeks to reduce dependence on materials such as neodymium and praseodymium, which are essential for energy and automative applications, thus promoting a more autonomous and sustainable supply chain for the purpose of magnet manufacture. A leap forward towards sustainable magnets in Europe With this planned increase in demand for rare earths in key sectors, the capacity to manufacture magnets without these elements is becoming a strategic priority. Within this context, the MagNEO project will be developing new AlNiCo (aluminium, nickel and cobalt) and HEA (high entropy) alloys, both of which are free of rare earths and perform well at high temperatures. These innovative magnets, which are made using state-of-the-art additive manufacturing techniques, are devised for applications in wind turbines, high-speed motors and other systems.

Ceit’s role

Ceit will pal yan essential role in the project, taking advantage of its previous experience with a laboratory-scale atomisation unit, together with its know-how in numerically simulating critical aspects of the gas atomisation process involving computational fluid dynamics (CFD) to increase the performance of its new industrial-scale atomisation unit, with which it is going to produce large batches of the powders needed to manufacture these new magnets. The gas atomisation process enables metal powders to be obtained with optimum features for use in different current additive manufacturing techniques. Ceit will be in charge of analysing the influence of the different operational variables, as well as designing and testing brand new, more efficient components to ensure the scalable industrial manufacture of sustainable magnets developed as part of the MagNEO project. Furthermore, it will be continuing with the task of computationally modelling the different stages in the process using multi-phase models, with a view to being able to predict the particle size distribution of the resulting powders and choose optimum atomisation conditions beforehand.

A more sustainable and autonomous Europe

The MagNEO project, coordinated by the Norwegian SINTEF research institute, involves the collaboration of sixteen partners from ten European countries, among which are included technological organisations, technology suppliers, manufacturers and universities.

MagNEO thus provides a great opportunity to reduce European dependency on critical materials by strengthening resilience of the supply chain in strategic sectors.

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency (HADEA). Neither the European Union nor the granting authority can be held responsible for them.