Advanced materials

We work on the design, processing and optimisation of metals and innovative materials, geared towards meeting the demand of complex environments and applications. Our research ranges from the design of new alloys and composite materials to their characterisation and validation. We work on key areas such as special steels, magnetic materials and ceramics, and on the development of specific solutions for applications in hostile environments, by integrating state-of-the-art manufacturing methods and simulation to ensure optimum properties and in-service performance.

Solutions

Special steels

We develop new compositions and grades of steel designed to maximise their performance, including the design of advanced microalloy steels, by analysing microalloy strategies in order to optimise both the manufacturing process and end product properties. We also work on the development of stainless steels and superalloys, providing solutions for the purpose of enhancing the behaviour of in-service material and its adaptability to different industrial processes.

Hard metal

We develop hard and superhard materials that require high resistance and accuracy. We work on cutting and warping tools – both hot and cold work.

Additionally, we work on the design of high-entropy alloys with advanced properties and research into superabrasive materials such as diamond and cubic boron nitride, creating high-precision dimensional components.

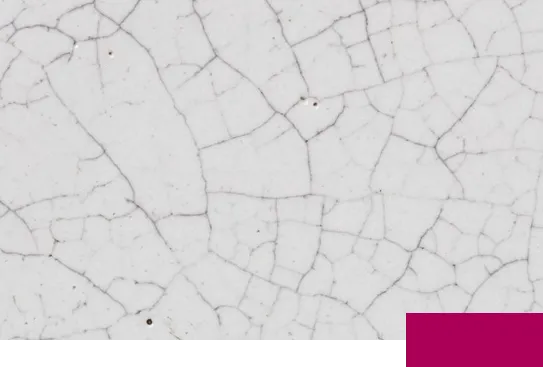

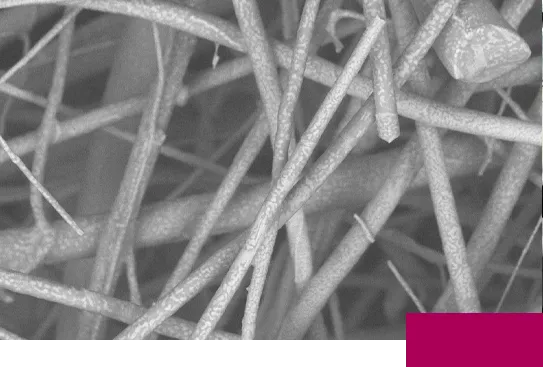

Ceramic materials

We research into fibrous ceramic components with high performance features, designed for demanding applications such as combustion systems. Our track record includes the development of porous materials based on advanced fibres such as silicon carbide (sic) and high silica, as well as the use of unclassified fibres. These solutions are geared towards optimising performance under extreme conditions, thus ensuring high thermal resistance and durability.

Magnetic materials

Hard and soft magnetic materials using advanced powder metallurgy routes that are adapted to a range of industrial applications. We have experience in the atomisation of powders such as fesib and ndfeb, as well as the design of magnetocaloric materials and mim processing of soft magnetic materials.

Materials for hostile environments

Advanced materials designed to operate under extreme conditions. We use technologies such as hot isostatic pressing (hip) to improve the density and mechanical properties of components. Additionally, we work on high-entropy alloys (heas) and special materials for nuclear fusion applications, thus ensuring optimum performance in environments with high temperature, radiation and pressure.

Materials for high temperatures

Materials designed to operate under extreme conditions of high temperature, thus ensuring optimum performance. Our track record covers nickel-based superalloys, which are recognised for their thermal and mechanical resistance, as well as advanced ceramic materials, which are ideal for applications in combustion systems and extreme environments..

Non-ferrous alloys

We work on high-performance, non-ferrous materials which are designed to meet the demands of critical applications in advanced industrial sectors. Our track record focuses on nickel-, copper-, titanium- and aluminium-based superalloys, optimising their mechanical and corrosion-resistant properties.